The majority of skate bearings demand minimal upkeep and survive a long period. If you ride your deck in puddles of water or other liquids, it’s probably a good idea to strip the bearings and reapply the grease. In general, every rider should know how to clean longboard bearings.

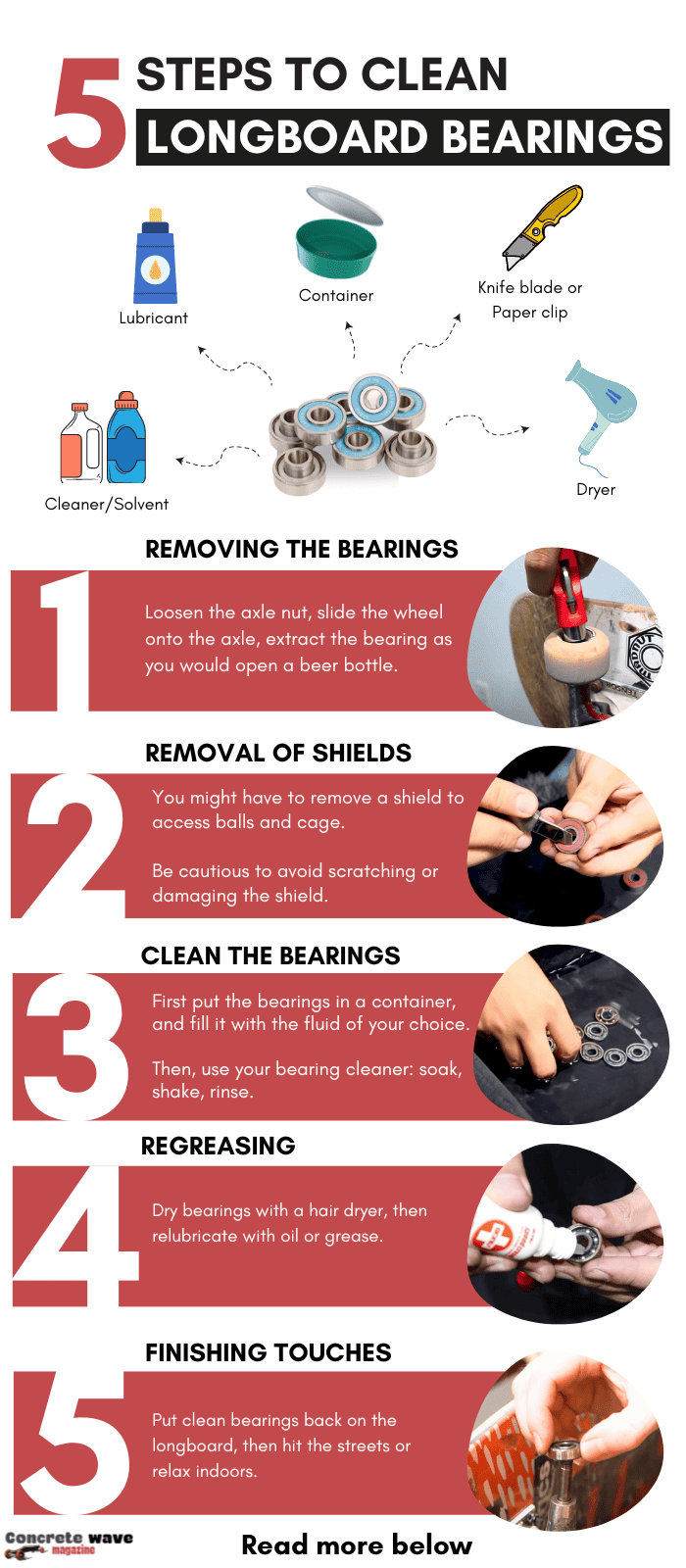

Only several steps are needed: removing the bearings, and the shields; cleaning the bearings; and lubricating them. Read on for more details.

Table of Contents

Materials Needed for the Process

Cleaner/Solvent

Cleaning bearings with alcohol or a citrus cleaner is common; the latter is safer but is more prone to leaving residues. A citrus cleaner is water-based; thus, you must dry your bearings as soon as possible to prevent rust.

The commercially available solvents are not as pure as you may think. Isopropyl alcohol, carburetor cleaning solutions, and acetone are some common examples. You must also dry them quickly.

Many boarders utilize alcohol-based cleaning products like methyl and ethanol. There are also other alternatives, such as engine degreasers and petrol.

What you use is all up to you. However, we encourage you to utilize eco-friendly approaches. Lemon juice is also effective.

Lubricant

When it comes to lubricants, the light grease option is our recommendation. But of course, it is entirely up to you.

The thinner the grease, the faster your bearings will spin, yet your bearings will be more likely to break. With medium grease, your bearings will be more difficult to dirty, but they will also spin slower. Thick grease will prevent water from getting in, but it will attract more filth.

A lubricant should be applied after cleaning longboard bearings so they operate smoothly; try to choose lubricants that don’t require a break-in period.

Container

Use a safe container with a lid and a cap, not a glass that is fragile and quickly breaks, or a container that is made of plastic that reacts with chemicals.

Knife blade or paper clip

A knife blade, a paper clip, or any other sharp instrument will be used to remove the shield. In most cases, something that is enough to eject the shield should be all that is required.

Dryer (optional)

A dryer is not necessary but might come in handy. If you want to dry your wet bearings quickly, or in order to make sure everything is dry all the way to the inner section, you should get this.

Steps on Cleaning Longboard Bearings

Step 1: Removing the bearings

Remove the nut from the axle, and slide the wheel on the axle (the innermost bearing should be on the edge of the axle). Take the bearing out of the wheel in the same manner as opening a bottle of beer. Repeat it on the other side.

Step 2: Removal of Shields

Most likely, you will have to remove one of the shields in order to get to the balls and cage. You’re probably going to scratch or damage the shield if you’re not cautious while taking it off. That’s okay though; you only need one on each bearing.

A “C” clip will be present around the exterior of the race for metal-shielded bearings. With some bearings, it is possible to completely remove the balls and cage from the race in order to perform individual cleaning, but unless you really want to do this, you don’t have to.

Step 3: Clean the bearings

To apply your own longboard bearing cleaning solution, first put the bearings in a container, and fill it with the fluid of your choice. Then, shake the bearings for about two minutes, then rinse the bearings with extra clean solvent.

Step 4: Regreasing

Use a hair dryer to dry your bearings, then use oil or grease to relubricate them. You don’t need a lot of lubrication, so use restraint!

Thinner lubricant yields faster bearing rotation, but it makes the bearings more susceptible to wear and tear.

Oil lubricates your bearings faster, but if anything comes into contact with them, your bearings will quickly wear out. In addition, oil tends to spin out of the bearing, causing bearings to overheat and wheels to melt. Too bad! However, you might be interested in checking it out if you love cleaning bearing surfaces all the time.

Thick grease, similar to the kind found in bike shops, is on the opposite extreme of the scale. If you use this, the good news is your bearings will withstand garbage, but the bad news is that they will spin more slowly. Your best bet is light grease or a specialized longboard bearing lube.

Step 5: Finishing Touches

Put the clean bearings back on the longboard, then take them to the streets! Or, relax in the house and watch the rain.

Tip: One may choose to save an old and heavily used set of bearings specifically for sliding and skating in the rain. Instead of corroding fresh bearings you just acquired for your board, this will keep them from rusting.

Conclusion

The bearings of your longboard gather grime and dirt over some period of time, which diminishes your ability to do some sick tricks. Cleaning the bearings is not hard, but it is highly effective. Cleaning your board’s bearings improves its speed and longevity, and can reduce natural wear and tear on the board.

The procedure is simple enough to perform at home, as explained in the instructions above. I hope this article helped you know about the importance of maintenance and how to clean longboard bearings.

I am Michael, and I have been enjoying this fun sport for seven years. And nothing is better than having a community to share our passion for those thrilling tricks. I am ready to tell you all I know about skateboarding, showing you how to choose a good board and trick to start and how the practice goes. Stay tuned!